With the continuous development of urban rail transit, the subway has become the preferred means of transportation for people's daily travel, and the main function of the air conditioning and ventilation system of the subway vehicle is to make the temperature, relative humidity, air flow speed and cleanliness of the passenger compartment (mainly dust Egypt). The carbon dioxide content is kept within the specified range to create a comfortable ride for passengers.

Classification of subway air conditioning ventilation system

Metro air conditioning ventilation systems are generally divided into open systems, closed systems and screened door systems.

1

Open system

The open system is the application of mechanical or "piston effect" method to exchange air inside and outside the subway, and use external air to cool the station and tunnel. This type of system is mostly used in subway systems with a monthly average temperature of less than 25 ° C and less traffic.

Piston ventilation

When the ratio of the front face of the train to the cross-sectional area of the tunnel (called the blocking ratio) is greater than 0.4, since the train travels at high speed in the tunnel, like the action of the piston, the air on the front of the train is pressed to form a positive pressure, and the air behind the train is thin. A negative pressure is formed, thereby generating air flow. Ventilation using this principle is called piston effect ventilation.

The amount of piston air volume is related to the blocking ratio of the train in the tunnel, the speed of the train, the air resistance coefficient of the train, and the resistance of the air flowing through the tunnel. The use of piston wind to cool the tunnel requires effective exchange of air with the outside world. Therefore, for all systems that use piston wind to cool the tunnel, the distance between the piston shaft and the cross-section of the wind should be calculated to achieve effective air exchange. Design requirements.

Experiments show that when the distance between the wind wells is less than 300m, the length of the air duct is less than 25m, and the air passage area is greater than 10m2, the effective air exchange volume is large. It is better to have a tuyere on the top of the tunnel. Since many piston wind shafts are difficult to implement in most cities, the entire "piston ventilation system" has only early subway applications. Today's subways are often equipped with a combination of piston ventilation and mechanical ventilation.

Mechanical ventilation

When the piston ventilation can not meet the requirements of the subway except for residual heat and residual humidity, a mechanical ventilation system should be set up.

According to the actual situation of the subway system, an independent ventilation system can be set up between the station and the section tunnel. The ventilation of the station is generally a horizontal air supply and exhaust system;

The interval tunnel is generally a longitudinal air supply and exhaust system. These systems should also have a smoke evacuation function. When the interval tunnel is long, it is advisable to have a middle wind well in the middle of the interval tunnel.

For the subway system where the local temperature is not high and the traffic volume is not large, a longitudinal ventilation system can be set up between the station and the section. Generally, a middle wind well is set in the middle of the section tunnel, but it should be determined by calculation.

2

Closed system

The closed system essentially isolates the interior of the subway from the outside atmosphere and supplies only the amount of fresh air required to meet passengers. The station generally adopts an air conditioning system, and the cooling of the section tunnel is realized by the "piston effect" of the train running a part of the station air conditioning cold air.

This kind of system is mostly used in the subway system in which the monthly average temperature of the hottest month in the local area is higher than 25 °C, and the volume of trains per hour and the number of trains per train in the peak time is greater than 180.

Open and closed system features:

Open and closed system application:

3

Screen door system

Install a screen door between the station platform and the road tunnel, separate it, install an air conditioning system at the station, use a ventilation system for tunnels (mechanical ventilation or piston ventilation, or both).

If the ventilation system cannot control the temperature of the interval tunnel within the allowable value, air conditioning or other effective cooling method should be used.

After installing the screen door, the station becomes a single building, which is not affected by the piston wind when the section tunnel is driving.

The air conditioning cold load of the station only needs to calculate the heat dissipation of the heating equipment such as the equipment, passengers, advertisements, and lighting of the station itself, and the heat transfer between the tunnel and the station through the screen door and the convective heat transfer when the screen door is opened.

At this time, the cold air load of the station door system is only 22%~28% of the closed system, and because the station is separated from the road tunnel, the interference of the running noise on the station is reduced, which not only makes the station environment quieter and more comfortable, but also Make passengers safer.

The subway environmental control system generally adopts a shielded door system or a closed loop control system.

The screen door system means that the platform and the rail line are separated. The station is an independent cooling and dehumidification area, so it has the advantages of safety, energy saving and aesthetics.

Screen door system function:

Screen door application:

Due to the partition of the screen door, the screen door system has formed two relatively independent systems: the station air conditioning ventilation system and the tunnel ventilation system.

1. Tunnel ventilation system:

It is divided into two parts: the interval tunnel ventilation system and the station tunnel ventilation system.

A. Interval tunnel piston wind and mechanical ventilation system (and smoke exhaust system), referred to as TVF system;

When the train is in normal operation, the piston wind generated by the train is replaced with the outdoor air to eliminate residual heat and residual moisture in the tunnel. For the two-station section without partition wall, the normal operating conditions also need to adopt mechanical ventilation. The wind is taken from the piston wind shaft at both ends of the station, and the TVF fan is used to exhaust the air.

In the event of a fire, the train stops in the interval tunnel. Then open the TVF fan and jet fan at both ends of the fire zone to provide fresh air and induce passengers to evacuate the fire site. The direction of smoke is determined according to the part of the train fire, and the minimum airflow speed is 2m3/s.

When the train is blocked in the interval tunnel, turn on the TVF fan as necessary to ensure that the train air conditioner can work normally. Under normal circumstances, the wind turbine is operated 0.5h before the daily subway operation and 0.5h after the end of the operation, for morning and evening cleaning and ventilation, to eliminate air odor and improve air quality.

B. In the station area, the heat removal under the shielded platform and the top heat removal system of the roadway, referred to as the UPE/OTE system.

2, station air conditioning ventilation system

It is divided into station public area ventilation and air conditioning system (and smoke exhaust system) referred to as large system, station equipment management room ventilation and air conditioning system (and smoke exhaust system) referred to as small system and air conditioning water system (referred to as water system).

Station equipment management houses mainly include equipment such as vehicle control room, stationmaster room, station office, conference room, bathroom and other equipment for operation and management, communication equipment room, signal room, substation, and environmental control room. According to the different functional requirements of each equipment management room, combined with the actual building layout, this part of the room can be classified into three categories: the first category, such as the car control room, conference room and other major management rooms, all need to be set. Comfortable air conditioning to meet the requirements of personnel and equipment; second type like communication room, signal room, etc.; third type such as bathroom.

The first type of room often uses air-water (fan coil and fresh air) system, the second type of room can use the full air system, the third type of room can use the full ventilation system, the use of the delivery and exhaust fans through the air duct and fire damper This type of room is ventilated.

When selecting the exhausting equipment, the commissioning of the ventilation and air-conditioning and exhaust system is based on the airflow of the ventilation and air-conditioning. Therefore, it is necessary to check whether the amount of smoke in each smoke-proof zone meets the area of 1m3/min. According to the literature, when the smoke prevention zone is divided, the area of each smoke prevention zone does not exceed 750 m2, and the smoke exhausting equipment is arranged according to the simultaneous elimination of the smoke volume of the two smokeproof zones to ensure that the smoke exhausting equipment can meet the smoke exhausting requirements in the event of a fire.

4

Exhaust system

1. The smoke exhaust system is set separately according to the station hall and platform, the section tunnel and the equipment management room.

(1) Smoke exhaust system in the station hall and platform. It is generally used in a normally ventilated exhaust system. The system shall meet the requirements for normal exhaust and smoke exhaust during fire;

(2) The smoke exhaust system of the interval tunnel should be a push-pull system with one vertical and one row. It is best to combine the ventilation system with the usual tunnel ventilation. Generally, a machine room is set at each end of the station, one fan is for one hole tunnel, and the two fans are spared for each other, and can also be operated in parallel. See the machine as a reversible axial fan, forward rotation can exhaust smoke. The air volume and wind pressure at the time of reversal should meet the requirements for smoke exhaustion;

(3) The smoke design of the equipment management room is set according to the requirements of the management house, and should be divided into one system according to the same use requirements. It is best to use it with the usual exhaust system;

2. The operation of the smoke exhaust system shall be carried out in accordance with the instructions of the underground railway disaster prevention system, and shall be arranged by the disaster prevention center. Generally, different operating modes are determined according to different fire locations, and are divided into:

(1) When the station platform is on fire, the smoke should be exhausted at the station, and the air is sent from the station hall, so that a flow from the station hall to the platform is formed at the stairway of the platform, and the speed should be greater than 3m/s. Passengers are evacuated from the platform to the station hall;

(2) When the station hall is on fire, the station hall will exhaust smoke and the platform will supply air to keep the platform at a certain positive pressure. Fresh air enters the station hall from the entrance and exit of the station hall, and passengers are moving in the direction of fresh air, and are evacuated from the entrance and exit to the ground;

(3) When the train is on fire in the section tunnel, the train should be driven to the station as much as possible to evacuate the passengers. At this time, the fan at the station end is exhausted and operated in the manner of fire on the platform. Once the train can't drive to the station, different modes of operation are taken when the following three conditions occur:

1 When the train head is on fire: When the train stays in the single-line tunnel for some reason, the passenger cannot withdraw from the side of the train. Only the tail safety gate enters the tunnel and evacuates to the station in the direction of the exit. At this time, the accident fan in the direction of the train entering the station exhausts the smoke, and the air blower from the accident fan in the outbound direction guides the passenger to evacuate against the fresh air;

2 When the tail of the train is on fire: the direction of evacuation of the passenger and the mode of operation of the exhaust are exactly opposite to those when the train head is on fire;

3 The car in the middle of the train is on fire: At this time, the passenger enters the tunnel at the same time from the front door and the safety door at the rear of the car.

The operation mode of smoke exhausting is: the air blower of the accident fan in the direction of the station, and the smoke of the accident fan in the outbound direction. Passengers getting off the front door safety door quickly evacuated to the station against the fresh air. Passengers getting off the rear safety door should be quickly evacuated to the communication channel connecting the two-hole tunnel in the direction of the smoke flow. The communication channel enters the other tunnel and is evacuated in the direction of air supply.

Although there is a small distance passengers with the same evacuation direction as the smoke flow direction, there is the possibility of being smoked by the smoke. However, due to the early stage of the fire, the tunnel center area has not been invaded by smoke, as long as there is organized, race against time, and fight for smoke. If the gas is filled before the tunnel is evacuated, it will not be smoked by the smoke, otherwise it will be quite dangerous.

Air conditioning ventilation system parameter standards:

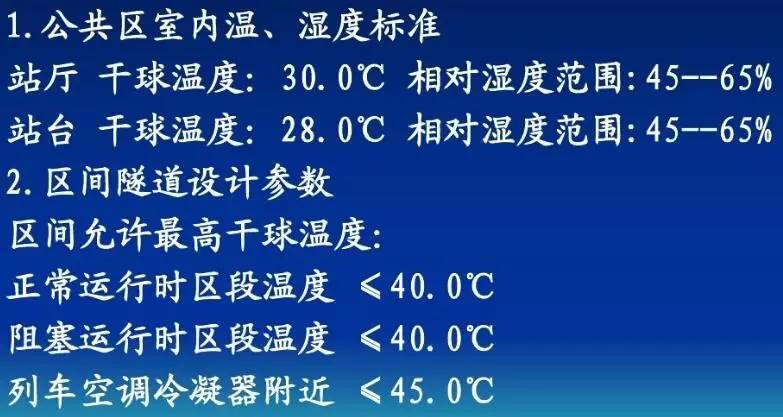

First, the temperature and humidity standards:

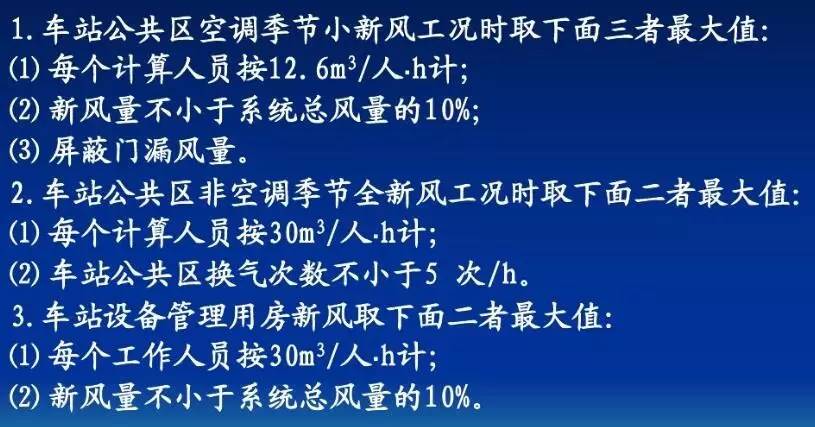

Second, the new wind standard:

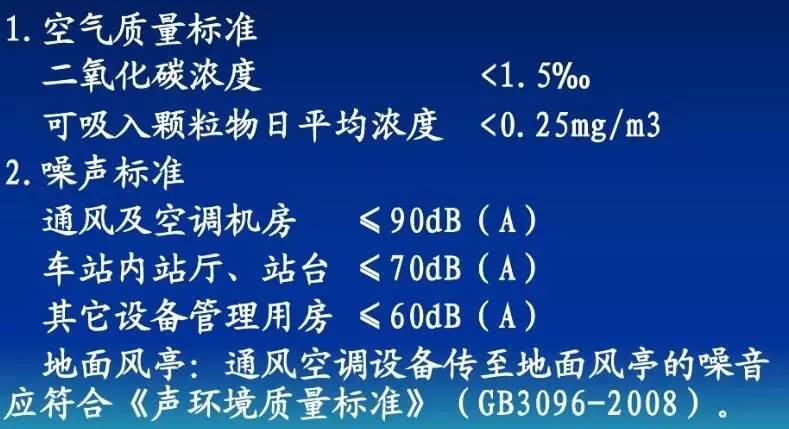

Third, air quality and noise standards:

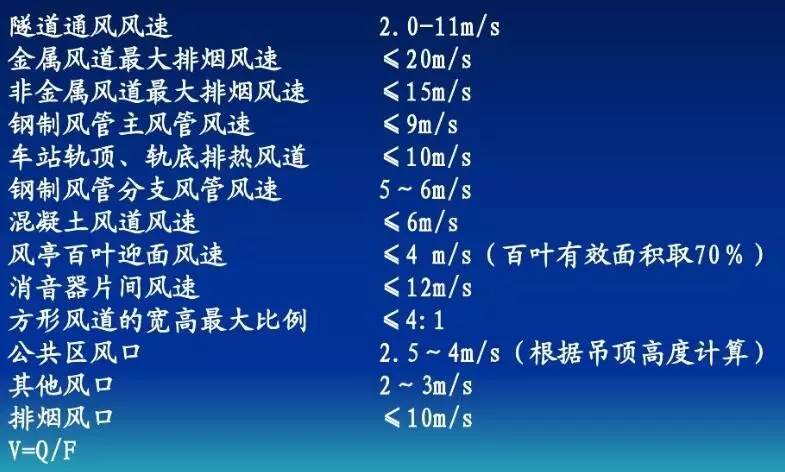

Fourth, the wind speed standard:

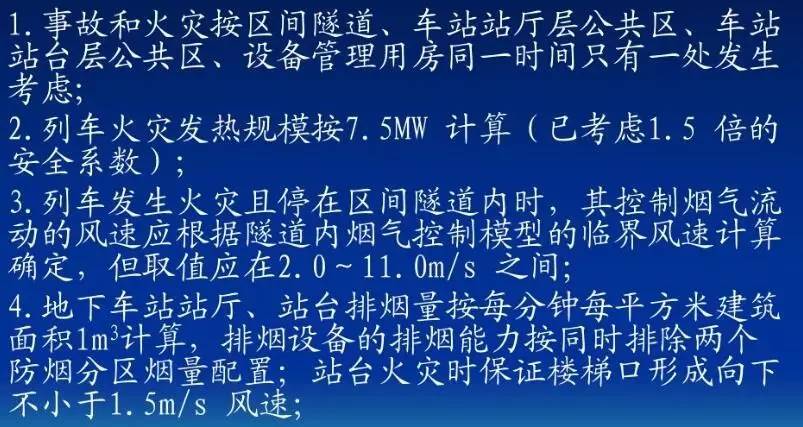

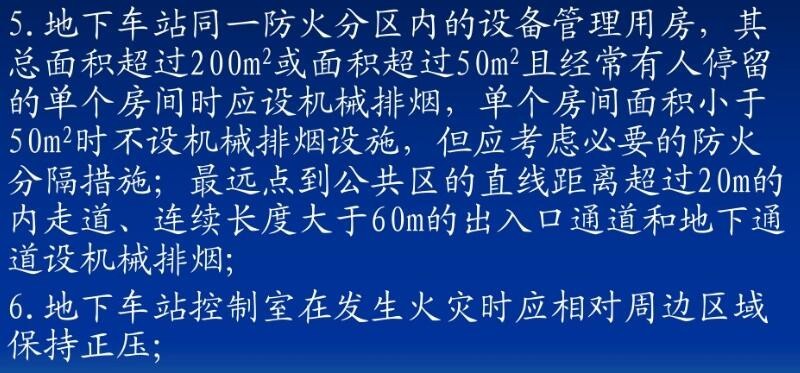

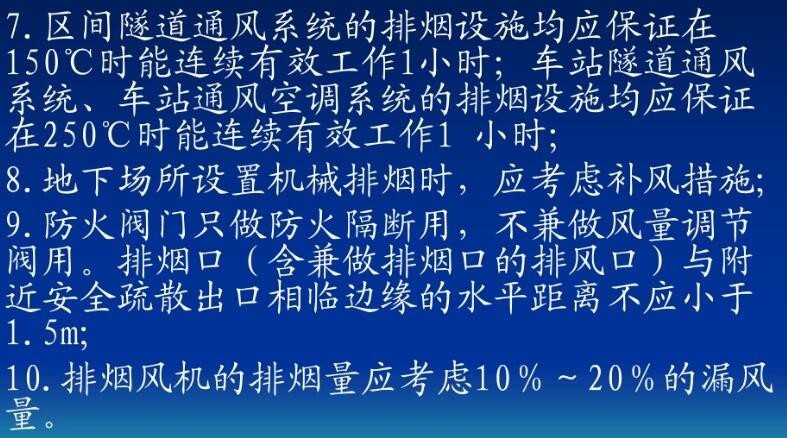

Fifth, anti-smoking standards:

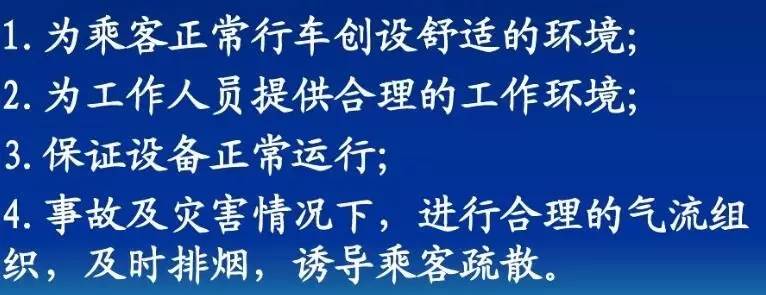

Air conditioning ventilation system four major functions:

(Content comes from the network finishing: China e car network)

Note: This article is organized by China e car network, please indicate the source!

FEEDBACK

Please fill in your requirements and receive your information and arrange for someone to contact you immediately.